You may have already seen my hardware integration demo where I combined iPads, iPhones, motors, barcodes, RFID, digital scale, mobile receipt printer, and payment cards. Here you can watch a video of the demo from FileMaker DevCon 2019:

And here is a short excerpt from my session I presenteda t the FileMaker Konferenz in Hamburg, where I showed the automated store demo not only from the user's perpective, but also what's under the hood:

Although everyone loved the automated moving parts built from LEGO, the after-session questions and discussions were mostly focused on RFID and NFC.

Even though RFID exists since 1946, it took until late 1990s for some useful standards to emerge. For some time the technology was widely used mostly for access control, animal and vehicle tracking, and manufacturing automation. But within the last 3-5 years we have seen an increase of interest in many other business areas, especially those within the target market of the FileMaker platform.

There are different standards, frequencies, polarizations, antennas, and chips available, depending on your actual needs. Whether you want to track assets and goods inventory, identify people or animals, automatically trigger actions in production line, or attach data to physical things and places, there is a good combination of technologies to use and it can be integrated with your FileMaker app.

So here are some of the most important and interesting facts about RFID which you may not have heard of yet but which can have significant impact on your decision on whether or which RFID technology to incorporate in your solution.

RFID can be read from short or long distance

Depending on the actual application, you can be able to read and write RFID tags from just a very short distance (less than 1 inch or 2 cm), a middle distance (up to 1 feet or 30 cm), or even a long distance (up to 30 feet or 10 meters). The two main factors affecting reading distance are frequency range and antenna size. Third is the amount and character of mass between the reader and the tag.

When selecting RFID technology, the fist question you should ask yourself is from what distance you would like to be able to read the tags and whether you need to clearly identify single tag or prefer to be able to scan multiple tags at a time. A simple rule is the higher reading distance ant the more tags you want to read at once the higher the frequency should be and the bigger the chip antenna.

The most commonly used are three frequency ranges:

- LF (low frequency between 120 and 150 kHz)

- HF (high frequency of 13.56 MHz)

- UHF (ultra-high frequency using 433 MHz and the range between 865 and 928 MHz)

Low Frequency

LF tags are typically readable from up to 1 foot (30 cm) but the reading range can be extended by antenna size and choice of materials to around 6 feet (2 m). We have used LF chips for any cases where individual item/tag needs to be clearly identified, such as door access control, patient charts in a hospital etc.

LF RFID has been also globally adopted as a standard for animal identification. That was the reason for coming up with a way to extend the reading range because some large animals, such as horses, don't make it easy to get the reader close enough to the identification tag. Our most recent use of LF tags is to identify products in an automated smart production line where materials and unfinished goods are being delivered to the right workstation after being noticed by a RFID reader.

High Frequency (including NFC)

HF range is currently the most emerging one. It is used for various purposes and there are many different standards and systems based on this frequency.

A huge subset of HF RFID applications is NFC, although it is not really just a subset. While RFID by its name is supposed to be used for identifying things where there is typically an active reader and a passive tag, NFC extends the use of the technology to a peer-to-peer communication where both communicating parties can be active.

HF tags can typically be read from up to 3 feet (1 meter). Some applications and readers, such as the mentioned contact-less pamynets, intentionally limit the reading distance for security or privacy reasons, while on the other side technology exists, commonly used by car thiefs for instance, to extend the reading distance, sometimes by repeating the tag's response by an active device.

Here you can watch a brief demo of NFC recorded in my sessions at FileMaker Konferenz in Hamburg and FileMaker Devcon Scandinavia in Helsingør:

Thanks to the extended definition of NFC, new applications keep appearing wherever it's useful to easily transfer small amounts of information between devices. One example is fire protection system inspection seal using SMARTRAC ratch tag containing information about the last inspection. Some museums, such as Museum of London, used NFC to attach information to exhibited items.

Ultra-High Frequency

Ultra-High Frequency

UHF has become the most widely used RFID frequency range so far. One of the main reasons is the reading distance, which can be over 50 feet (15 m), and reading speed.

One difficulty with using the high frequency, however, is that it falls into range with high level of regulation. When UHF RFID began to be deployed, there was not a single frequency in the 900 MHz range which would still available globally around the world, so there had to be different ranges reserved for it in different locations. It's goot to keep in mind that using frequency range that's not allowed for RFID in your country is illegal.

The most common use of UHF RFID is in identifying goods, assets, and parts to optimize workflows and save time in production lines, warehouses, and shops. We have recently used UHF RFID tags in the JOGS project for our customer in Africa to identify sacks of crops purchased from local farmers in Malawi.

RFID tags can be read even from metal parts

Many RFID tags, especially on the UHF range, are hard to reliably read when they are attached to metal or water containers, or whent there is metal or water between the reader and the tag.

Interestingly one of the industries with the widest application of RFID is automotive. It is probably due to the high level of automation and efficiency, so any technology that can save manufacturing time can pay for itself relatively fast.

To be able to use them on the metal car parts, RFID tag vendors came up with tags that can work reliably. Some tags use a special layer of material to enforce the tag antenna's distance from the metal surface, some tags go even further and smartly use the metal surface as an extension of the antenna.

So if you work with metalic equipment and materials, don't hesitate to consider using RFID if it provides a chance for you to make your processes more efficient. You just have to select the right tags and equipment to use.

RFID can be read one-by-one or in large batches

You will chose different hardware depending on whether you want to identify individual tags or quickly scan multiple tags at once. What you might not know is that the most powerful readers are able to scan hundreds of tags per second quite reliably, so for instance you can have a solution that scans all the contents of a package without having to open it.

This is the case of UHF tags, where the 900MHz frequency allows for faster communication. For instance a handheld RFID reader with circular polarization we had a chance to explore, can read up to 200 tags per second from up to 7 meters. That really makes it possible to scan the contents of one box or pallet of goods within a second, without having to unpack it.

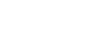

RFID can be smoothly integrated with FileMaker on iOS

Many mobile barcode and RFID readers can operate as HID (Human Interface Device), simulating external keyboard entry. Using such reader saves on cost but it's very difficult to make sure the user interface of your app is ready for it then the user scans an item, and that the user does not use the device when the interface is not ready for it. The user also has to avoid touching the screen while the reader types in the data.

Luckily, the iOS App SDK available from Claris as part of the FileMaker Developer Subscription benefits allows plug-ins to be used with FileMaker on iOS. So, when working on the JOGS project, where we needed to implement a smooth user experience needing little or no support from our side, we decided to use a plug-in.

The plug-in made our implementation as easy as using a single script step to read the RFID tag and even allowed us to have the reader automatically run our script when it detected a new RFID tag.

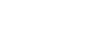

NFC can be read and written with iPhone

iPhone 7 or later can read and write NFC tags without any additional hardware devices. How much support your iPhone has for reading and writing NFC tags depends on the phone model and version of iOS.

iPhone Xs, Xr, 11 or 11 Pro can even read NFC tags with encoded URL on the system level, without installing a special NFC reading/writing app. Custom apps are able to read NFC on iPhone 7 or later running iOS 11 or later. Writing to NFC requires iOS 13.

FileMaker Go 18 does not leverage NFC yet, but just like the other RFID integrations, this functionality can be added with a plug-in.

Tag casing is the most expensive part

One of the reasons for the recent rise of the RFID popularity must be the fact that the RFID tags became much cheaper. In the past, frequency range used to be the main price denominator but it is no longer so. Actually, the casing of the tag is the most expensive part of it.

If you are fine with plain paper labels, you can find producers from China offering them for $0.0045 if you buy them in large quantities. Printable labels from the reliable brands, such as Alien, Zebra, or Smartrac, are typically priced between $0.10 and $0.50 depending on flavor and quantity you buy.

What makes RFID tags more expensive is when you request better casing material (such as plastic, glass or ceramic), larger antenna (to increase reading distance), durability, reliability, larger on-chip memory for data storage, smart applications built into the chip etc. For instance, printable plastic cards we used in our project cost $1.70 per card.

Theory vs Practice

The most important aspect of any hardware integration is the gap between theory and practice. And I admit we experienced this gap with every single new hardware technology we integrated. The point is that even if you read all the Wikipedia descriptions, vendor materials, documentation, and web forums, such as SourceForge or StackOverflow, if you have not worked with that technology before, you will have to go through a trial-error learning path that will cost you at least significant amount of time, but often also money spent on wrong hardware, simply because you will have to figure out things that are not written anywhere.

On our path to integrating RFID with FileMaker, for instance, we started with LF RFID from Phidgets and learned that we can choose from read-only tags and rewritable tags and we can choose between reader and reader/writer. But when later exploring UHF RFID, it was difficult to find rewritable tags and UHF RFID writers. Until we discovered that writing to tags is so commonly required in the UHF range that vendors simply automatically assume it and don't feel the need to promote it. So if you find an UHF RFID reader, there is almost zero chance that it will not be able to also write to the tags.

On our path to integrating RFID with FileMaker, for instance, we started with LF RFID from Phidgets and learned that we can choose from read-only tags and rewritable tags and we can choose between reader and reader/writer. But when later exploring UHF RFID, it was difficult to find rewritable tags and UHF RFID writers. Until we discovered that writing to tags is so commonly required in the UHF range that vendors simply automatically assume it and don't feel the need to promote it. So if you find an UHF RFID reader, there is almost zero chance that it will not be able to also write to the tags.

Another thing we had to find out ourselves is that writing to a LF RFID tag while it's moving and passing by the reader/writer, can fail so badly when the tag is not close to the reader/writer for long enough that it becomes unreadable and unwritable. When using RFID for automation, you may need to adjust the speed in which things move around in order to make reading or writing their RFID tags more reliable.

Conclusion

There probably can't be a better time to start using RFID or NFC. If you work in an industry that already uses it, you simply have to use it to remain competitive. In all other industries, RFID has the potential to make some of your processes more efficient. If you start using it now you can set yourself ahead of your competitors.

If you're new to RFID and don't want to hire an experienced RFID implementor, it's better to start small and implement a prototype as a proof of concept first, before deploying it widely across your business, so that you keep the cost of your learning reasonable. It's worth trying different tags and different hardware to find out what will provide the level of comfort and reliability you're looking for.

It will be interesting to see what new and innovative RFID applications appear in the next few years. Will yours be one of them?